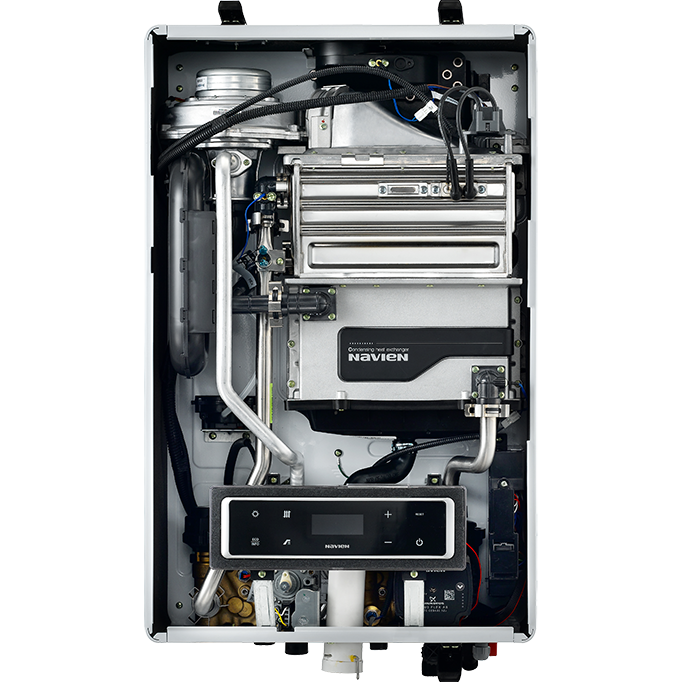

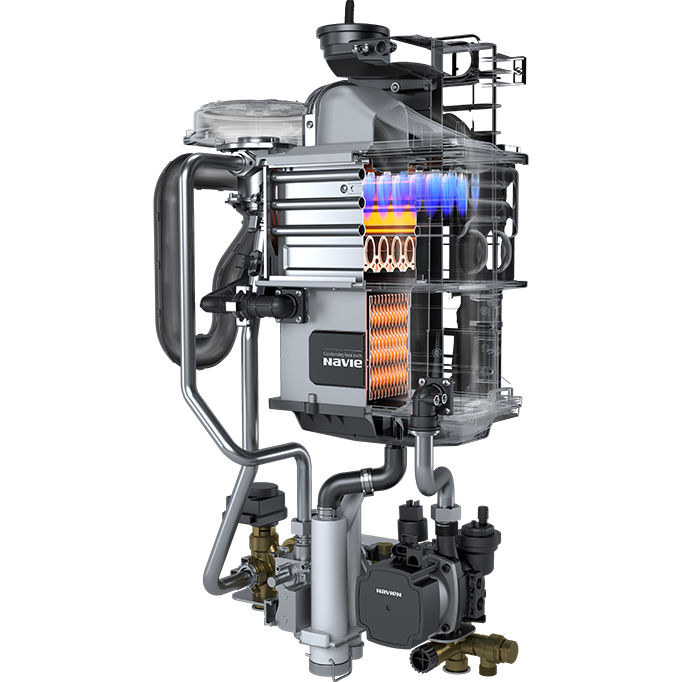

NCB-CE System Boiler for installers

The NCB-CE system boiler range is comprised of four A-rated system boiler models, ranging from 20 to 33kW. Whilst the models vary in terms of output, they all have easy and cost-effective installation in common.

- Smartphone compatible offering remote adjustments of heating and hot water systems

- ErP A+ energy efficiency rating*

- Smart weather forecasting and Geofencing

- Durable stainless steel heat exchangers

- 3-zone ready w/ Smart Plus control pack

- IPX5 rating

- 7-year parts and labour warranty

- Extended venting up to 20m allowing flexible installation

* An A+ energy rating is achieved when installed with 3 Smart Plus room thermostats.

Technical Data

| NCB-20LHWE | NCB-24LHWE | NCB-28LHWE | NCB-33LHWE | ||

| Heat Output | Heat input range | 20.0/4.2kW | 24.0/4.2kW | 29.0/5.1kW | 34.0/4.0kW |

| Modulation (max/min) | 1:10 | 1:10 | 1:10 | 1:10 | |

| Heat output range @ 80/60°C | 19.5/3.9kW | 23.4/3.9kW | 28.3/4.9kW | 33.2/3.8kW | |

| Condensing heat output range @ 50/30°C | 21.4/4.5kW | 25.6/4.5kW | 31.1/5.4kW | 36.3/4.3kW | |

| Full load efficiency at Max./Min. output @ 50/30°C (Condensing) | 106.9/107.8kW | 106.6/107.8kW | 107.3/106.9kW | 106.9/106.9kW | |

| Max. heating operation pressure | 2.5 bar | ||||

| Max. heating temperature | 90oC | ||||

| Adjustable heating temperature range | 40-90oC | ||||

| Flue | Flue exhaust/Air intake system diameters | Coaxial Ø60/100 and Ø80/125–Dual duct Ø80/80 | |||

| Max. horizontal coaxial length ø60/100 | 20m | ||||

| Max. horizontal coaxial length ø80/125 | 68m | ||||

| Weight | 38 | 42 | |||

| Dimensions | 440 x 358 x 695mm | 440 x 408 x 695mm | |||

| ErP Efficiency | ErP A (94%) | ||||

| ErP Efficiency with Smart Plus (x3) | ErP A+ (98%) | ||||

| NOx Classification | Class 6 | ||||

Downloads

NCB-CE Gas Condensing Boiler FAQs

What does the fault code E302 mean for NCB-CE boiler?

E302 This means that the system pressure is too low and you may see that the system pressure gauge indicates that the pressure in the system is below the 1 bar pressure.

To re-pressurise the system you will find a filling loop (copper ‘U’ shaped tube with two nuts at each end) on the underside of the boiler or a metal braded flexible hose external of the boiler on the pipework with one or two tap connections at the either end of the filling loop. The tap or taps should be opened a quarter of a turn and the water will start to refill the system (water should be heard filling the system). You should see the pressure gauge rise back up between 1 bar and 1.7 bar pressure and then stop filling.

Boiler information on water pressure can also be seen on the digital display by pressing the Eco button for 6 seconds and then scroll through to ‘A6’ which will display the water pressure. Once the pressure gauge between 1 bar and 1.7 bar turn the taps back to the off position and the water will stop filling the system. The error code 118 will stop and the boiler will now operate. If the error code 118 is still active, fill up the system a little more but not over 2.0 bar.

(If you do fill the system too much and the pressure gauge is too high, just bleed water from a radiator until the pressure on the gauge goes down to below1.7 bar).

To re-pressurise the system you will find a filling loop (metal braided flexible hose) on the underside of the boiler with two tap connections at either end of the filling loop. One small blue & one small black tap handles. The taps should be opened a quarter of a turn. Open the small black one and then open slowly the small blue one. The water will start to refill the system (water should be heard filling the system). You should see the pressure gauge rise back up between 1 bar and 1.2 bar pressure and then stop filling.

Once the pressure gauge is between 1 bar and 1.2 bar turn the taps back to the off position and the water will stop filling the system. The error code E302 will stop and the boiler will now operate. If the error code E302 is still active, fill up the system a little more but not over 1.5 bar.

(If you do fill the system too much and the pressure gauge is too high, just bleed water from a radiator until the pressure on the gauge goes down to below 1.2 bar).